Our company has designed, produced and installed more than 8,000 production lines of various sizes and continues to provide them with technical support.

Understand the needs of users, and explain to the use, output and price of the equipment.

Many users will visit our company to learn more about the equipment and technology.

Technical engineers design the plan and check it several times to ensure that the plan is effective and efficient.

High-precision processing and production of equipment, strict control of product quality

After the equipment is finished, the user can come to the factory for inspection or online video inspection, or appoint a third party for inspection.

Use wooden boxes, protective films, etc. to protect the machine from damage, and track land and sea transportation throughout the entire process.

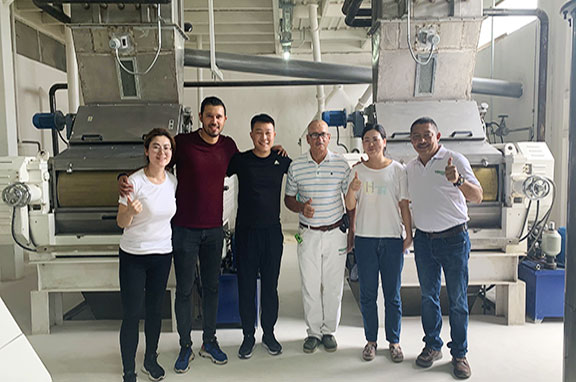

Engineers will guide the installation and commissioning and train workers in the field to ensure the normal operation of the equipment and processing.

7*24 hours after-sales service, quickly solve problems for users.

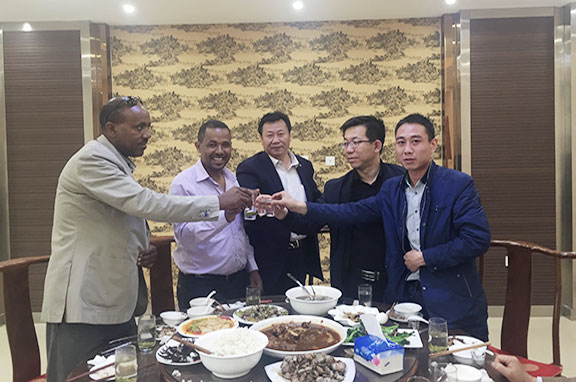

Users have given high praise to our equipment and have become friends with us. Some users have ordered our equipment for expansion and production many times.

Below are frequently asked questions, you may find the answer for yourself